Offering Description

- Product/Process Improvement

- In-depth analysis of a product or process related problem to find underlying key problems

- Solution development suitable for different time lines (incremental as well as disruptive ideas)

- Much more comprehensive than Tech Scouting

- Solutions substantiation (reasons to believe)

- Support for IP (patent) preparation

Background

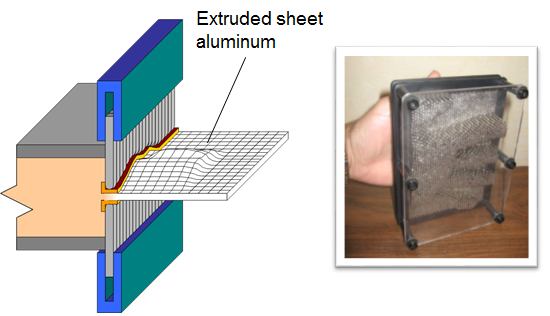

- A car body includes number of aluminum sheet parts with complex shape.

- The current technology includes sheet extrusion, multi-step stamping and welding.

- Due to large number of operations and applying complex equipment, the current technology is too expensive

- It is necessary to reduce operation cost dramatically

- What should be done?

Trimming and Physical Contradiction

- The problem:

- How to reduce the operation cost?

- Trimming:

- It is necessary to exclude majority of operations from the technological process and delegate their useful functions to one operation: extrusion

- Trimming problem:

- How to extrude an aluminum sheet with complex shape?

- Physical contradiction:

- The die should have one particular shape to provide specific cross-section of the aluminum sheet, but it should have another shape to provide another cross-section

- Separation in time: the die should be able to change its shape in the process of aluminum sheet extrusion

- Inventive Principle: Dynamicity (divide an object to parts capable to move relatively each other.

Solution: Dynamic Extrusion

Idea Description:

- Extrude aluminum sheet with complex shape using existing dies and additional equipment

Benefits:

- Reduced number of steps in the technological process

- Reduced tooling costs

- Productivity close to that of conventional extrusion

- Higher quality of the produced components, which are shaped when aluminum is in a malleable solid state; stamping aluminum in a solid state leads to high stress areas

- Option to change the shape (design flexibility) in terms of thickness and profile

- Weight savings due to improved mechanical performance